Welding

With the application of advanced smelting and rolling technology as well as microalloy strengthening technology, Baosteel hot-rolled high strength steel is featured by good weldability, which is obtained by reducing carbon equivalent and welding crack sensitive factor through low carbon low alloy design.

| Typical grade | Carbon equivalent C,% |

Carbon equivalen CE |

|---|---|---|

| B750L | ≤0.08 | 0.40 |

| B700L | ≤0.08 | 0.34 |

| B650L | ≤0.08 | 0.29 |

| B600L | ≤0.08 | 0.23 |

| HR60 | ≤0.08 | 0.16 |

| BR330/580DP | ≤0.08 | 0.15 |

![]()

Cold crack

Compared with other high strength steel, Baosteel’s hot-rolled high strength automotive steel is featured by low hardenability and excellent resistance to cold crack because of low carbon equivalent. Therefore, when the ambient temperature is higher than 00C, Baosteel’s hot-rolled high strength steel can be welded without preheating and welding cracks tend not to occur.

Compared with other high strength steel, Baosteel’s hot-rolled high strength automotive steel is featured by low hardenability and excellent resistance to cold crack because of low carbon equivalent. Therefore, when the ambient temperature is higher than 00C, Baosteel’s hot-rolled high strength steel can be welded without preheating and welding cracks tend not to occur.

Preparation before welding

Impurities on the welding area should be removed to keep it clean and dry.

Welding method

MAG, SMAW, SAW can be used for Baosteel hot-rolled high strength steel for automobile. It is recommended to use MAG.

Welding heat input

Using the recommended welding heat input can ensure good mechanical properties of the heat-affected zone. Besides, the wider range of heat input, the better the weldability of the steel.

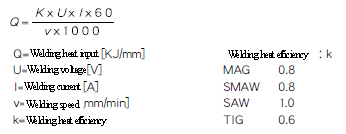

Welding heat input can be calculated by the following formula:

The following graph shows the recommended best welding heat input range according to the thickness of the steel sheet:

Baosteel’s hot-rolled high strength automotive steel has good weldability as it has a wide range of welding heat input for a certain thickness.

Groove shapes

Baosteel’s hot-rolled high strength automotive steel is suitable for various types of welding joints. Commonly used shapes include I-shaped grooves and V-shaped grooves.。